When you drop off your favorite silk blouse at the dry cleaner, it’s going on a fascinating chemical odyssey that’s honestly more sophisticated than I initially realized. The machine tumbles your garments in a drum filled with solvents like perchloroethylene, which dissolves those stubborn oil-based stains that water simply can’t handle. The used solvent then gets recycled through distillation systems with impressive 99.99% recovery rates, and there’s so much more happening behind those shop doors.

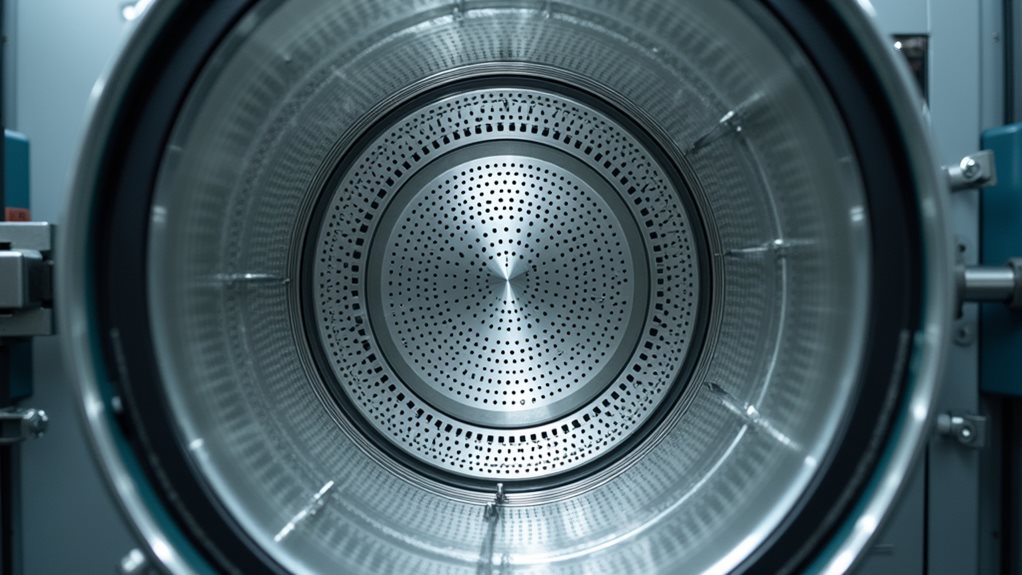

The Basic Operation of Dry Cleaning Machines

When I first watched a dry cleaning machine in action, I honestly thought it looked like a fancy washing machine having an identity crisis – and in some ways, that’s not entirely wrong!

A dry cleaning machine is basically a washing machine that decided to get fancy and develop trust issues with water.

These dry cleaning machines work by tumbling your garments in a drum while pumping in solvent, typically perchloroethylene, to tackle stubborn stains that water just can’t handle.

The cleaning process becomes surprisingly sophisticated when the used solvent gets whisked away to a distillation unit, where it’s purified and recycled like liquid gold ♻️.

Modern multi-solvent machines have revolutionized cleaning efficiency by letting operators choose the perfect solvent for different fabrics, all while staying compliant with strict environmental regulations – because nobody wants angry regulators knocking on their door!

After the cleaning cycle completes, the garments go through a drying phase where the solvent evaporates, leaving clothes clean and ready for the final pressing and finishing steps.

Solvent Types and Their Role in the Cleaning Process

The magic truly happens when you understand that not all solvents are created equal, and choosing the right one can make the difference between rescuing your favorite silk blouse and turning it into an expensive cleaning disaster 😅.

Perchloroethylene, the traditional dry cleaning solvent champion, tackles oil-based stains like nobody’s business, but it’s basically the environmental villain of chemical solvents.

That’s why modern dry cleaning machines are embracing eco-friendly alternatives like liquid carbon dioxide and silicone-based cleaning agents, which deliver impressive results without the nasty environmental impact.

Different solvent types work best with specific fabrics, so your cleaner’s expertise in matching the right cleaning process to your garment becomes essential for preserving both quality and longevity.

Other petroleum-based options like Stoddard solvent and petroleum spirits have also been employed in dry cleaning operations, though they come with varying degrees of effectiveness and environmental considerations.

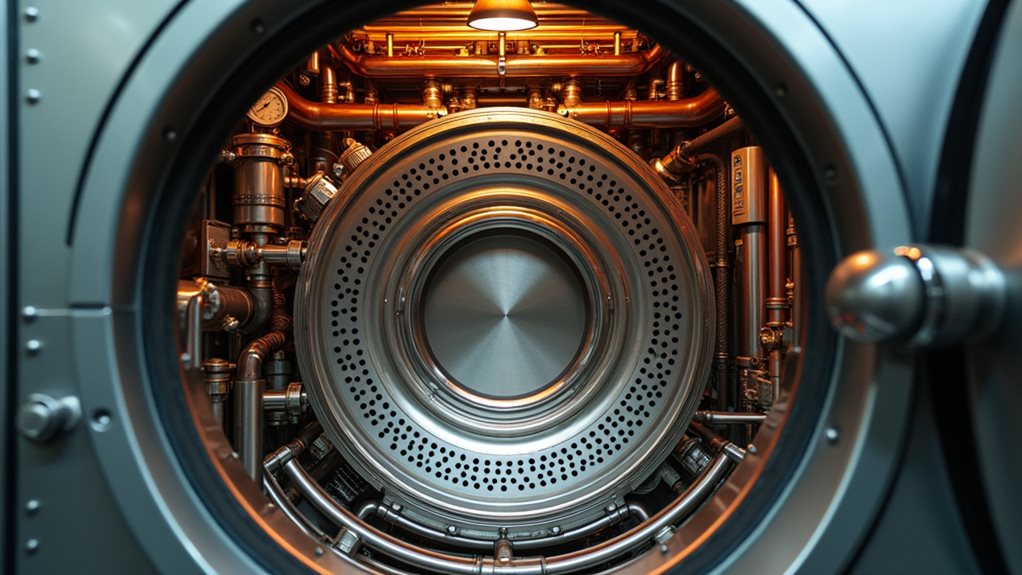

Machine Components and Their Functions

Picture a sophisticated orchestra where each instrument plays its part in perfect harmony, and you’ll understand how dry cleaning machine components work together to transform your stained garments into pristine pieces.

Your dry cleaning machine’s drum gently cradles delicate fabrics while the solvent delivery system pumps cleaning solvent throughout, saturating every fiber with precision.

Once dirt’s conquered, the extraction system whisks away used solvent to a distillation unit, where it’s purified for another performance.

Meanwhile, the drying system circulates warm air, evaporating remaining solvent while capturing vapors—because nobody wants chemicals floating around! 🌿

Advanced filtration systems work behind the scenes, removing impurities and guaranteeing compliance with environmental regulations, making each cleaning cycle both effective and eco-conscious.

The most commonly used cleaning solvent is perchloroethylene, which effectively dissolves oils and grease that traditional water-based washing cannot remove.

Solvent Recovery and Distillation Systems

Efficiency becomes the heartbeat of every successful dry cleaning operation, and that’s exactly where solvent recovery and distillation systems shine their brightest.

You’ll discover these ingenious mechanisms extract used solvent from garments after the cleaning phase, transforming what could be waste into liquid gold for your business.

Here’s how these systems revolutionize your operation:

- Advanced filtration techniques remove contaminants before recycling solvent back into cleaning cycles.

- Distillation systems vaporize impurities, condensing clean solvent for maximum reuse efficiency.

- Recovery rates reach an impressive 99.99%, dramatically reducing environmental impact while slashing operational costs.

The distillation process ensures that perchloroethylene and other solvents evaporate completely without leaving residues, maintaining the high cleaning standards your customers expect.

Modern solvent recovery systems aren’t just environmentally responsible—they’re financially brilliant!

Environmental Controls and Safety Features

When I first stepped into a modern dry cleaning facility, I was honestly amazed by how seriously these machines take worker safety and environmental protection—it’s like they’ve got their own personal bodyguard system! 🛡️

You’ll find that today’s dry cleaning equipment comes loaded with sophisticated environmental controls that would make even the most cautious safety inspector smile, from advanced air filtration systems that capture every wisp of solvent vapor to real-time monitoring sensors that constantly check emission levels and chemical concentrations.

These closed-loop systems guarantee solvent vapors get condensed and recycled, maintaining excellent air quality while minimizing worker exposure to harmful chemicals.

The automatic shut-off mechanisms act like vigilant guardians, preventing spills and accidents while keeping operations in perfect compliance with environmental regulations.

Many facilities now offer eco-friendly cleaning methods like wet cleaning and CO2 cleaning as alternatives to traditional perchloroethylene-based processes.